1. Introduction

Foam conversion has quietly become one of the most essential industrial processes in 2025. Whether it’s designing bespoke acoustics for a recording studio, improving sound absorption in construction vehicles, or creating thermal insulation in marine environments — foam conversion plays a vital role in transforming raw foam materials into specialized, high-performing solutions.

But what exactly is foam conversion, and why is it increasingly crucial across multiple sectors? This article explores how foam conversion works, its diverse applications, and how companies like Acoustafoam have refined this process to deliver unmatched precision and acoustic performance.

2. What is Foam Conversion?

Foam conversion refers to the transformation of foam materials into specific shapes, sizes, or products that serve unique purposes. This isn’t just simple cutting — it’s a technical process that turns a standard piece of foam into a custom-engineered acoustic or insulation solution.

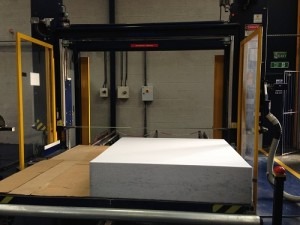

Different methods are used depending on the project requirements. From band saws, profiled slitters, laminators, CNC profiling machines, die-cut presses, and water jets, each technique helps achieve exact measurements and consistent quality.

The outcome? Tailored foam components that meet precise performance demands — whether for sound absorption, thermal control, or mechanical protection.

3. The Science Behind Foam Conversion

Foam materials are incredibly versatile. They can be engineered for softness, durability, insulation, or sound control. The most commonly converted foams include:

- Polyurethane Foam: Soft, flexible, and used in cushions, insulation, and acoustic panels.

- Polystyrene Foam: Lightweight and rigid, ideal for insulation and packaging.

- Polyethylene Foam: Tough, moisture-resistant, and perfect for protective padding or industrial applications.

The conversion process enhances these natural properties through cutting, laminating, moulding, or profiling. By combining various materials or coatings, foam can become fire-resistant, sound-absorbing, or even thermally insulating, depending on the end use.

4. Foam Conversion in Action: From Concept to Custom Solution

When a business requires a bespoke acoustic solution, foam conversion offers limitless possibilities. For instance:

- Construction Vehicles: Foam can be shaped to absorb sound around radiators or engines, reducing noise pollution and improving comfort.

- Marine Applications: Specialized foams with foil-facing fronts are used for thermal insulation and soundproofing in yacht engine rooms.

- Industrial Machinery: High-density foams provide vibration damping and sound absorption in heavy equipment.

- Automotive Interiors: Custom-cut foams are used for headliners, armrests, and acoustic barriers.

Each application begins with identifying a problem — such as excessive noise or heat — and ends with a tailored foam conversion that solves it efficiently and safely.

5. Bespoke Acoustics: The Heart of Modern Sound Management

In the field of acoustics, foam conversion is revolutionary. Using advanced CNC profiling machines and laminating systems, foam can be turned into shapes like wedges, pyramids, or egg crates — forms designed to absorb and scatter sound waves effectively.

These bespoke acoustic foams are used in:

- Recording studios and cinemas for echo reduction

- Office environments for better speech clarity

- Public buildings and gyms to control reverberation

- Industrial spaces for noise management

Each design is carefully calculated to meet a specific acoustic goal. For example, low-density foams absorb mid-to-high frequencies, while thicker, high-density foams are perfect for managing bass or low-frequency vibrations.

6. The Role of Class 0 Foam in Safety and Performance

One of the most innovative materials in foam conversion is Class 0 foam — a high-performance, fire-resistant material.

It’s treated with a mineral compound that gives it a nil burn rate, making it ideal for applications with a high fire risk. Class 0 foam is not only safe but also extremely effective at sound absorption.

Applications include:

- Engine rooms

- Generator canopies

- Heavy vehicles

- Marine environments

Key Benefits:

- Non-toxic and flexible

- Easy to cut and install

- Resistant to erosion and migration

- Available with self-adhesive backing and foil facings

The FireTech Profile, a flexible open-celled polyurethane foam, is a prime example of how foam conversion enhances both safety and sound performance simultaneously.

7. The Benefits of Foam Conversion

Foam conversion delivers a host of advantages that go beyond simple material modification.

a. Precision Engineering

CNC cutting and water jet technologies allow exact dimensions, ensuring that every piece fits perfectly into its application.

b. Customization

No two industries have the same acoustic or insulation needs. Foam conversion allows for complete customization — from density and size to shape and coating.

c. Durability and Longevity

Converted foams are designed to withstand wear, moisture, and environmental conditions, maintaining performance over time.

d. Environmental Responsibility

Many manufacturers are now incorporating eco-friendly or recycled foams, minimizing waste and reducing environmental impact.

e. Enhanced Performance

Whether it’s improving sound quality, increasing comfort, or preventing heat transfer — converted foams are engineered to deliver results.

8. Quality Control and Industry Expertise

In professional foam conversion, quality control is non-negotiable. Each product undergoes rigorous testing to ensure compliance with acoustic, safety, and durability standards.

Companies like Acoustafoam lead the market by combining decades of technical experience with state-of-the-art equipment. Their expertise in both foam conversion and bespoke acoustics allows them to create reliable solutions for automotive, marine, construction, and industrial clients alike.

9. How Foam Conversion Enhances Modern Acoustic Design

Modern acoustic design demands more than aesthetics — it requires scientific precision. Foam conversion makes this possible by allowing designers to integrate acoustic materials into walls, ceilings, and machinery seamlessly.

By profiling foams into specific patterns, sound waves are managed more efficiently, preventing echo, vibration, and unwanted noise. This makes bespoke acoustic foam an essential component of today’s architecture and engineering projects.

10. Conclusion: The Future of Foam Conversion

As industries continue to evolve, the need for smart, sustainable, and specialized materials will only grow. Foam conversion stands at the forefront of this transformation — offering practical, customizable, and eco-conscious solutions for a wide range of applications.

From bespoke acoustic systems to fire-safe Class 0 foams, the process continues to redefine how we manage sound, temperature, and comfort across environments.

If you’re looking to elevate your acoustic performance or need expert guidance on foam conversion, now is the time to explore tailored solutions.

Contact Acoustafoam today to discover how innovative foam conversion can help your business achieve precision, safety, and performance — all in one engineered product.